The advent of Electric Vehicles, featuring quieter drivetrains and stiffer geometries, has prompted an intense focus on phenomena affecting Ride Comfort, such as NVH (Noise, Vibration, Harshness) and BSR (Buzz, Squeak, Rattle). To support these efforts in South Korea, Gyeongnam Technopark (GNTP) recently worked with the MTS Korea TestStand Group to build a set of chassis NVH test systems, using modular MTS components and locally sourced, MTS-designed fixturing.

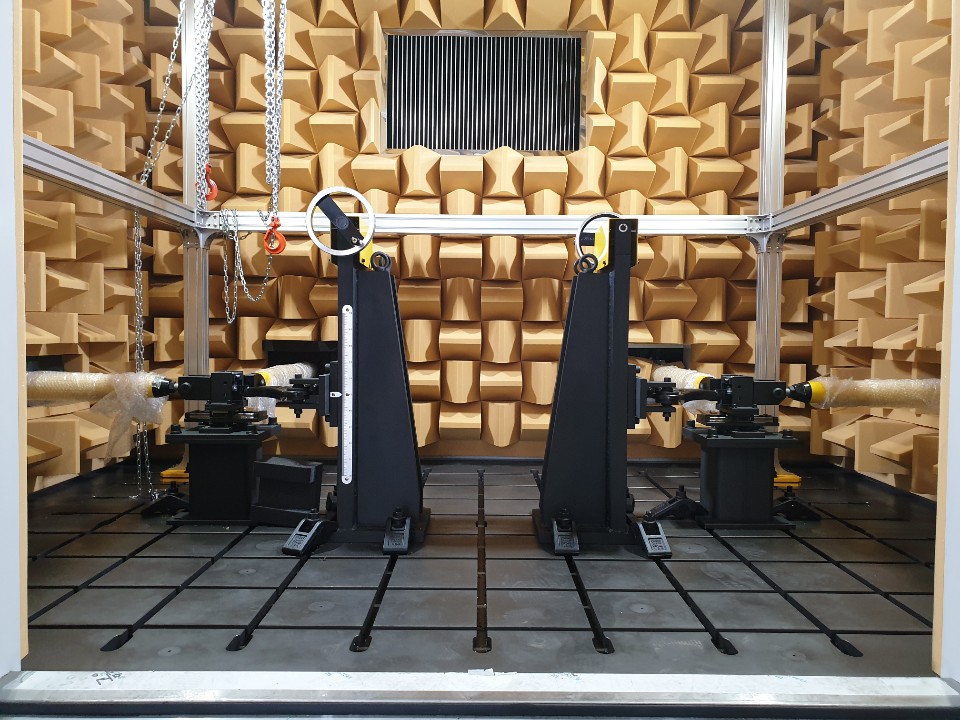

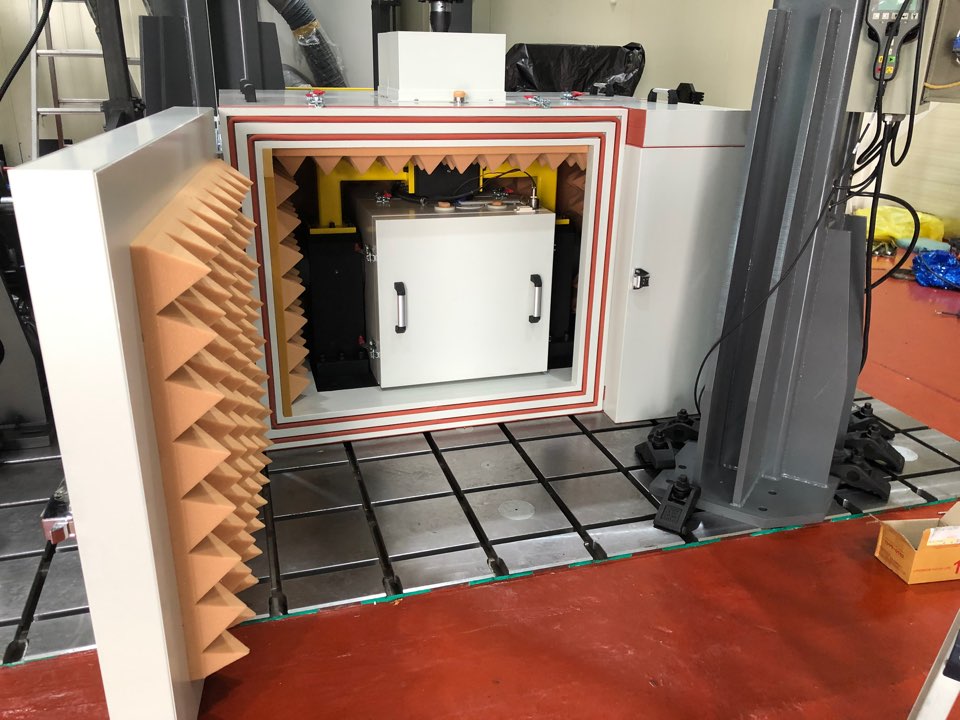

The GNTP Chassis NVH Solution comprises two 4-channel test systems: a Chassis Component Test Stand (left) and a Bushing Test Stand (right). Capable of block cyclic testing and time history playout at up to 20Hz in climate-controlled conditions, both test stands are engineered to subject test specimens to real-world vibration conditions for detection and evaluation of BSR and NVH phenomena. Learn more about Gyeongnam Technopark (GNTP).

|

4-Channel Component Test Stand |

4-Channel Bushing Test Stand |

|

|

|

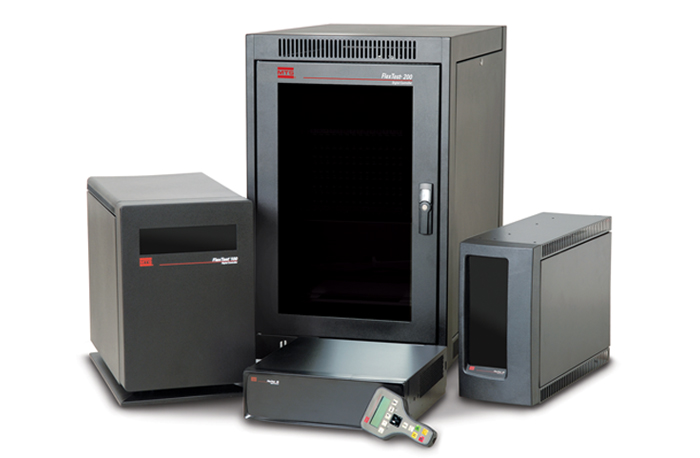

RPC® Software |

|

|

FlexTest® 60 Controllers 4-station, 4-channel (one per test stand) |

|

|

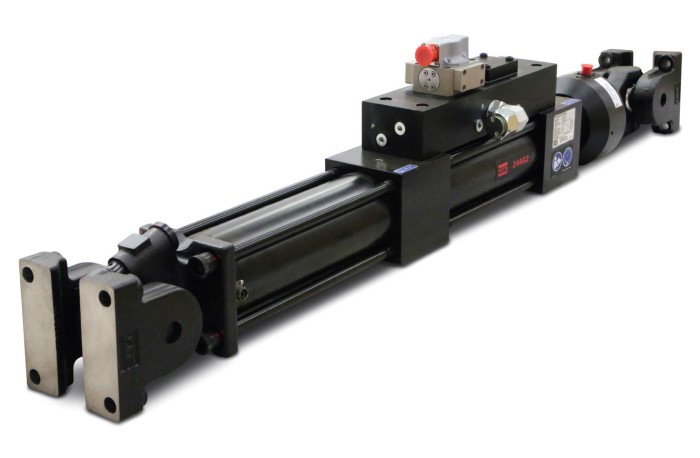

MTS DuraGlide® Actuators |

|

|

2 x Model 244.12 (25kN, 150mm stroke) |

2 x Model 244.12 (25kN, 100mm stroke) |

|

2 x Model 244.21 (50kN, 150mm stroke) |

Model 244.21 (50kN, 100mm stroke) |

|

|

Model 215.35 (565 N-m / 5000lbf-in) |

|

Model 293.22 HSMs 2-Station (one per test stand) |

|

|

System Fixture Assemblies (locally sourced) |

|

|

4 x T-slot base, 4 x mounting fixture, 2 x bell crank, 4 x strut, specimen fixture |

T-slot base, portal frame, 3 x mounting, specimen fixture |

|

Environmental / Anechoic Chamber |

Anechoic Chamber - outer |

|

|

Environmental Chamber - inner |

|

SilentFlo HPU |

|

|

BSR Evaluation Kits (GNTP Supplied) |

|