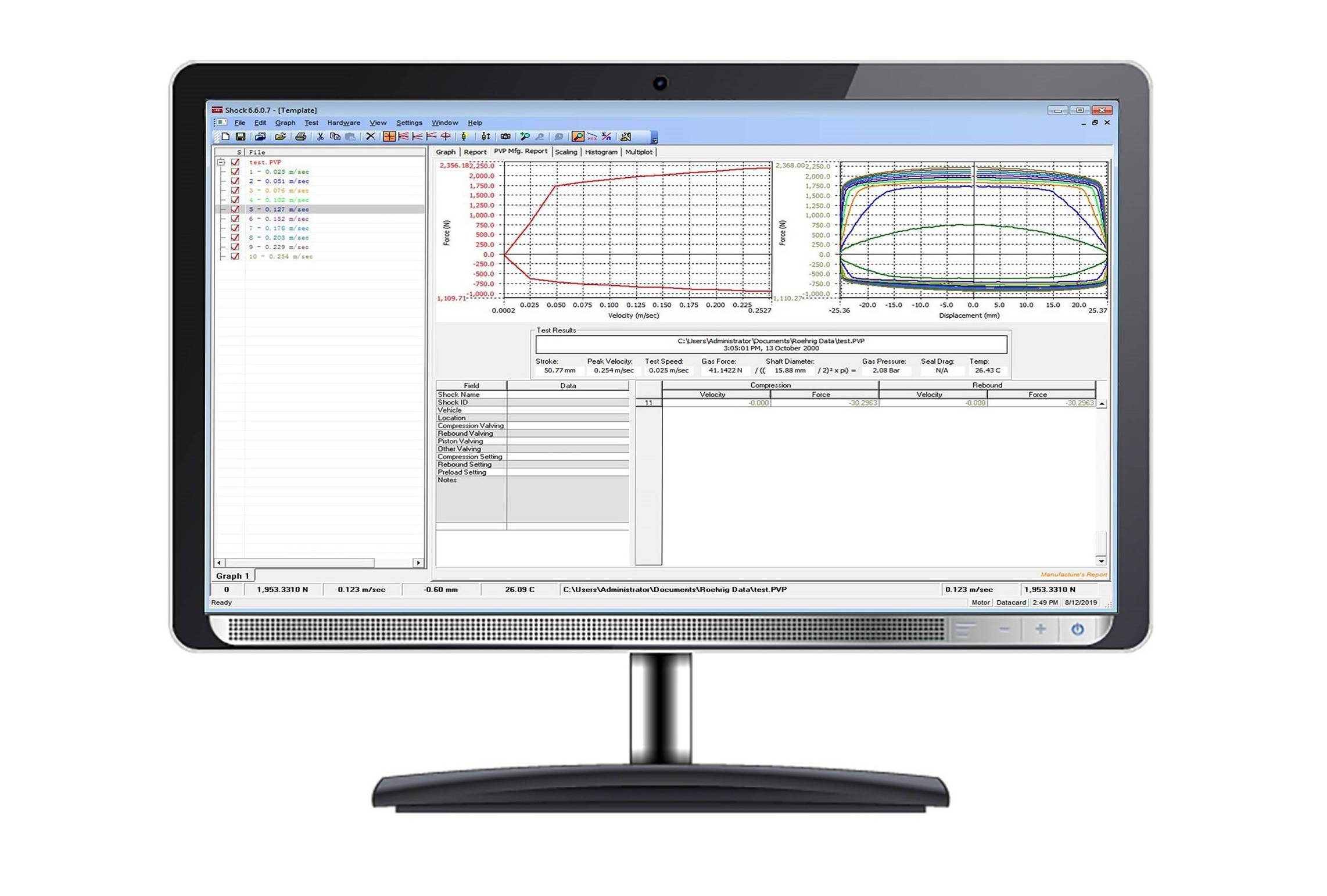

To ensure safety and durability, high-performance mountain bike suspensions and components must be subjected to punishing real-world shock and vibration phenomena for extended test periods. Fox Factory Inc. conducts testing and research on its racing forks and shocks in a state-of-the-art laboratory equipped with advanced MTS shock and damper testing technology.

Testing High-performance Bike Suspensions

Kurt Siever and Ariel Lindsley provide a look into the Fox test lab, exploring the methods and technologies used to simulate real world usage and ensure that high-performance shocks and forks are safe enough for the world's most powerful riders and punishing courses.

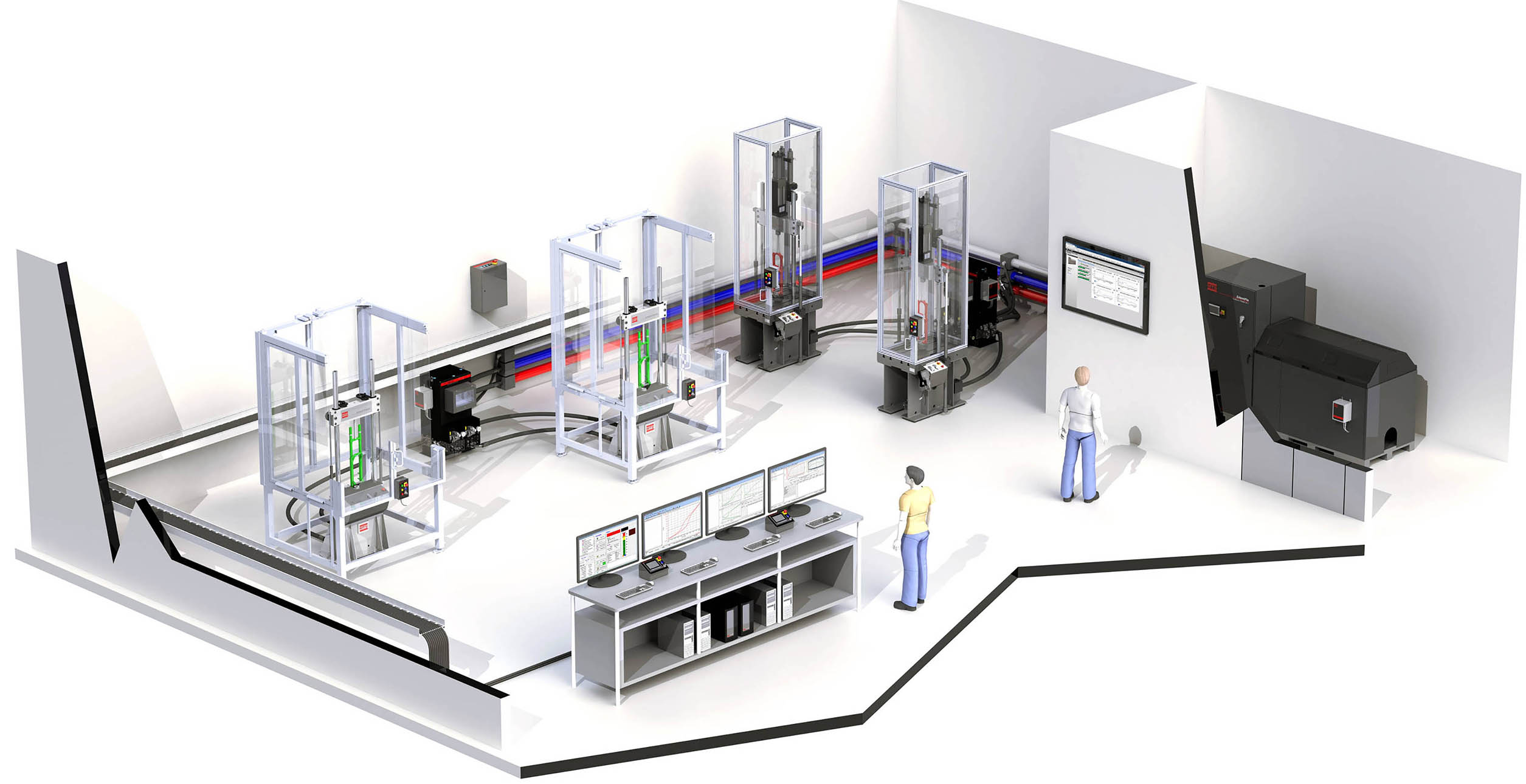

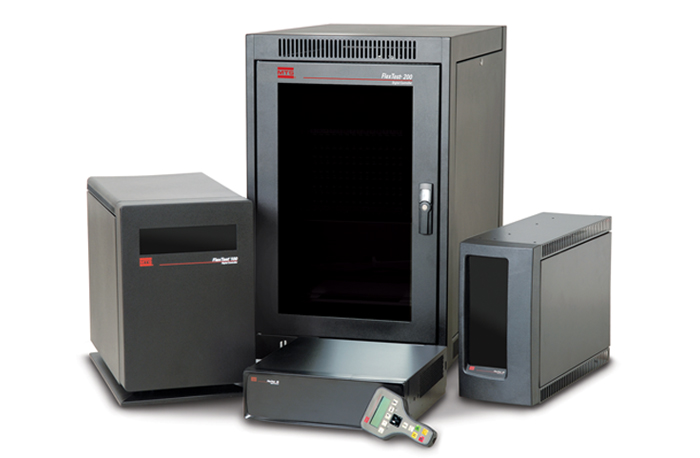

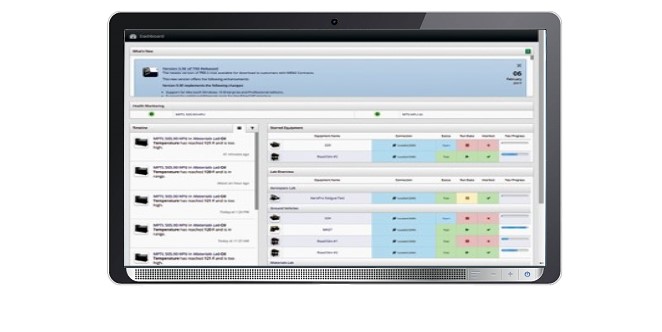

The Fox laboratory employs a tightly integrated array of MTS servohydraulic test systems and infrastructure that are engineered to maximize testing accuracy, operational efficiency and safety.