Series 647 All-Temperature Hydraulic Wedge Grips

Series 647 All-Temperature Grips can be operated within an environmental chamber at temperatures up to 1000°F (540°C). Two models are available: one with a range from –130 to 315°C (–200°F to +600°F), and the other from –130 to 540°C (–200°F to +1000°F).

Applications

- Tension

- Shear

- Fracture

- Fatigue

- Compression

- Torsion

- 180 Degree Peel

Test Specimens

- Ceramics

- Metals

- Composites

- Plastics

Test Standards

- ASTM D3039

- ASTM D3518

- ASTM E21

- ASTM E517

- ASTM E646

- ASTM E8-E8M

- ISO 10113

- ISO 10275

- ISO 6892-1

- ISO 6892-2

- ISO 14129

- ISO 527-4

- ISO 527-5

- EN 2561

- EN 2597

- EN 6031

Key Product Features

Rapid Specimen Changeover

Remote opening and closing allows specimens to be changed quickly

Accurate

Low thermal gradients minimize risk of thermal stress on specimen

Adjustable Pressure

Hydraulic pressure can be adjusted, allowing these grips to be used for testing a variety of materials

Multiple Wedge Selection

A wide variety of wedges are available to meet your testing requirements

Full Product Information

Precision, easy-to-load grips for a wide range of tensile and fatigue applications

Series 647 All-Temperature Grips provide all the advantages of our popular Series 647 Hydraulic Wedge Grips in a design that can be operated within an environmental chamber at temperatures up to 1000°F (540°C). Two models are available: one with a range from –130 to 315°C (–200°F to +600°F), and the other from –130 to 540°C (–200°F to +1000°F). These grips are opened and closed remotely, so there is no need to cool them down before changing specimens. Rapid specimen changeover can be accomplished without touching the hot gripping device. In addition, because the grip head operates within the chamber—at test temperatures— thermal gradients between the grip and specimen are minimized. When these grips are used within an MTS environmental chamber, gradients as low as ±3°F (1.6°C) can be achieved.

As with all MTS hydraulic grips, these provide a constant, adjustable gripping force, regardless of the test loads applied. This consistency prevents specimen slippage or damage to soft specimens during testing. When actuated, all moving parts of the grips are hydraulically locked in place so the specimen can be cycled from full tension to full compression without backlash.

Wedges for these grips are available in many configurations for testing both flat and round specimens. To minimize potential damage to your specimen shaft, you can order our flat wedges with an optional Surfalloy™ finish. This rough, tungsten carbide surface coating provides firm gripping of even the most brittle composites to deliver more accurate, repeatable material characterization.

|

647 ALL-TEMPERATURE HYDRAULIC WEDGE GRIPS |

||||||||||||

|

Specifications |

||||||||||||

|

MODEL |

TEMPERATURE |

FORCE RATING |

FORCE RATING |

UPPER WEIGHT |

LOWER WEIGHT |

STUD SIZE |

||||||

|

647.02A-31 |

–200 to 600°F |

5.5 kip |

7.0 kip |

31 lb |

36 lb |

1/2-20 |

||||||

|

647.02A-32 |

–130 to 315°C |

25 kN |

31 kN |

14 kg |

17 kg |

M12 x 1.25 |

||||||

|

647.02A-51 |

–200 to 1000°F |

5.5 kip |

7.0 kip |

31 lb |

36 lb |

1/2-20 |

||||||

|

647.02A-52 |

–130 to 540°C |

25 kN |

31 kN |

14 kg |

17 kg |

M12 x 1.25 |

||||||

|

647.10A-31 |

–200 to 600°F |

22 kip |

27 kip |

125 lb |

142 lb |

1-14 |

||||||

|

647.10A-32 |

–130 to 315°C |

100 kN |

120 kN |

57 kg |

65 kg |

M27 x 2 |

||||||

|

647.10A-51 |

–200 to 1000°F |

22 kip |

27 kip |

125 lb |

142 lb |

1-14 |

||||||

|

647.10A-52 |

–130 to 540°C |

100 kN |

120 kN |

57 kg |

65 kg |

M27 x 2 |

||||||

|

647.25A-31 |

–200 to 600°F |

55 kip |

75 kip |

269 lb |

289 lb |

1-1/2-12 |

||||||

|

647.25A-32 |

–130 to 315°C |

250 kN |

333 kN |

122 kg |

131 kg |

M36 x 2 |

||||||

|

647.25A-51 |

–200 to 1000°F |

55 kip |

75 kip |

269 lb |

289 lb |

1-1/2-12 |

||||||

|

647.25A-52 |

–130 to 540°C |

250 kN |

333 kN |

122 kg |

131 kg |

M36 x 2 |

||||||

|

Note: Grip weights would change with different extension lengths. Contact MTS for more information. |

||||||||||||

|

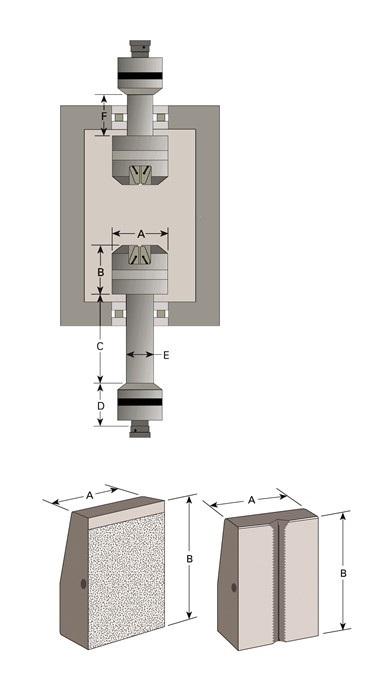

Dimensions |

||||||||||||

|

Model Number |

A |

B |

C* |

D |

E |

F* |

||||||

|

647.02 |

114 mm |

112 mm |

267 mm |

94 to 112 mm |

66 mm |

150 mm |

||||||

|

647.1 |

203 mm |

160 mm |

297 mm |

117 to 132 mm |

99 mm |

155 mm |

||||||

|

647.25 |

267 mm |

226 mm |

285 mm |

142 to 168 mm |

122 mm |

165 mm |

||||||

|

* Note: Other grip extension lengths are available. Contact MTS for more information. |

||||||||||||

|

Wedge Selection |

|

|||||||||||

|

GRIP MODEL |

WEDGE SHAPE |

SPECIMEN THICKNESS OR DIAMETER |

SPECIMEN THICKNESS OR DIAMETER |

WEDGE DIMENSIONS |

WEDGE DIMENSIONS |

|

||||||

|

647.02 |

Flat |

0 to 0.28 |

0 to 7.1 |

25 mm (1.0 in) |

38 mm (1.5 in) |

|

||||||

|

647.02 |

Flat |

0.28 to 0.57 |

7.1 to 14.4 |

25 mm (1.0 in) |

38 mm (1.5 in) |

|

||||||

|

647.02 |

Vee |

0.12 to 0.32/0.37 |

3.0 to 8.1/9.4 |

25 mm (1.0 in) |

38 mm (1.5 in) |

|

||||||

|

647.02 |

Vee |

0.35 to 0.43/0.60 |

8.9 to 10.9/15.2 |

25 mm (1.0 in) |

38 mm (1.5 in) |

|

||||||

|

647.1 |

Flat |

0 to 0.30 |

0 to 7.6 |

45 mm (1.75 in) |

64 mm (2.5 in) |

|

||||||

|

647.1 |

Flat |

0.28 to 0.56 |

7.1 to 14.2 |

45 mm (1.75 in) |

64 mm (2.5 in) |

|

||||||

|

647.1 |

Vee |

0.23 to 0.40/0.47 |

5.84 to 10.2/11.9 |

45 mm (1.75 in) |

64 mm (2.5 in) |

|

||||||

|

647.1 |

Vee |

0.43 to 0.50/0.65 |

10.9 to 12.7/16.5 |

45 mm (1.75 in) |

64 mm (2.5 in) |

|

||||||

|

647.1 |

Flat |

0.46 to 0.75 |

11.7 to 19.0 |

45 mm (1.75 in) |

64 mm (2.5 in) |

|

||||||

|

647.25 |

Flat |

0.04 to 0.47 |

1.0 to 11.9 |

50 mm (2.0 in) |

89 mm (3.5 in) |

|

||||||

|

647.25 |

Flat |

0.24 to 0.67 |

6.1 to 17.0 |

50 mm (2.0 in) |

89 mm (3.5 in) |

|

||||||

|

647.25 |

Flat |

0.59 to 1.02 |

15.0 to 25.9 |

50 mm (2.0 in) |

89 mm (3.5 in) |

|

||||||

|

647.25 |

Vee |

0.42 to 0.66/0.78 |

10.7 to 16.8/19.8 |

50 mm (2.0 in) |

89 mm (3.5 in) |

|

||||||

|

647.25 |

Vee |

0.66 to 0.79/1.03 |

16.8 to 20.1/26.1 |

50 mm (2.0 in) |

89 mm (3.5 in) |

|

||||||

|

647.25 |

Vee |

0.25 to 0.40/0.53 |

6.4 to 10.2/13.4 |

50 mm (2.0 in) |

89 mm (3.5 in) |

|

||||||

|

* Maximum specimen diameter for vee wedges is based on loading specimen from top, not side. |

|

|||||||||||

|

|

|

|

|

|||||||||

GET THE MOST OUT OF YOUR INVESTMENT

Our experts are here to help keep you up and running

Related Products, Parts or Accessories

Series 651 Environmental Chambers

Landmark® Servohydraulic Test Systems

Criterion® Electromechanical Test Systems

Thermomechanical Fatigue (TMF) Subsystem

Looking for more products?

Go to Solution Finder