Criterion® Electromechanical Test Systems

Systems with force capacities from 1 to 600 kN (220 to 132,000 lbf), high-speed, low vibration electromechanical drives and integrated, digital closed-loop controls provide higher fidelity across test runs. Proven and easy to use, these systems efficiently deliver reliable results. Accessories to support a wide range of specimens at forces from 600 kN (132,000 lbf) down to 1 N (0.2 lbf).

Applications

- Tension

- Compression

- Flex/Bend

- Shear

Test Specimens

- Metals

- Aluminum

- Plastics

- Elastomeric Materials

-

Composites

- Carbon Fiber

- Ceramic Matrix Composites

- Composites

- Metal Matrix Composites

- Polymer Matrix

Test Standards

- ASTM D3039

- ASTM A48-A48M

- ASTM D3518

- ASTM D412

- ASTM D624

- ASTM D6272

- ASTM D638

- ASTM D695

- ASTM D790

- ASTM D882

- ASTM E21

- ASTM E290

- ASTM E517

- ASTM E646

- ASTM E8-E8M

- ASTM E9

- ISO 10113

- ISO 10275

- ISO 14125

- ISO 6892-1

- ISO 6892-2

- ISO 7438

- ISO 14129

- ISO 178

- ISO 527-2

- ISO 527-3

- ISO 527-4

- ISO 527-5

- ISO 604

- EN 2561

- EN 2562

- EN 2597

- EN 2746

- EN 6031

Key Product Features

Precise

Industry-leading 5000 Hz data acquisition rate provides better understanding of material characteristics

Accurate / Repeatable Results

Compact AC servomotor drives provide high-speed, low-vibration testing

Easy, Intuitive Use

TEDS-enabled load cells automatically download calibration information

Innovative Technology

TestSuite TW Software and custom test templates easily address complex tests

Model Comparison

Models C41 & C42

- Maximum rated force capacity:

- C41.103: 1 kN (220 lbf)

- C42.503: 5 kN (1100 lbf)

- Single-column

- Tabletop

- Standard and extended height

Model C43

- Maximum rated force capacity:

- C43.104: 10 kN (2200 lbf)

- C43.304: 30 kN (6600 lbf)

- C43.504: 50 kN (11000 lbf)

- Dual-column

- Tabletop

- Standard and extended height

Model C44

- Maximum rated force capacity:

- C44.304: 30 kN (6600 lbf)

- Dual-column

- Floor-standing

- Standard and extended height

Model C45

- Maximum rated force capacity:

- C45.504: 50 kN (11000 lbf)

- C45.105: 100 kN (22500 lbf)

- C45.305: 300 kN (66000 lbf)

- C45.605: 600 kN (132000 lbf)

- Dual-column

- Floor-standing

- Standard and extended height

- Wide and multihead configurations available

WHAT'S NEW / TRENDS

Featured Case Studies

Full Product Information

MTS CRITERION SERIES 40 SPECIFICATIONS - COMPARATIVE

|

|

|

Model 41 |

Model 42 |

|

Model 43 |

|

Model 44 |

|

|

|

C41.103 |

C42.503 |

C43.104 |

C43.304 |

C43.504 |

C44.304 |

|

Maximum Rated Force Capacity |

kN lbf |

1 220 |

5 1100 |

10 2200 |

30 6600 |

50 11000 |

30 6600 |

|

Force Capacity Options |

N, kN |

1 N, 5 N, 25 N, 50 N, 100 N, 250 N, 500 N, 1 kN |

1 N, 5 N, 10 N, 25 N, 50 N, 100 N, 250 N, 500 N, 1 kN, 2 kN, 5 kN |

100 N, 250 N, 500 N, 1 kN, 2.5 kN, 5 kN, 10 kN |

100 N, 250 N, 500 N, 1 kN, 2.5 kN, 5 kN, 10 kN, 20 kN, 30 kN |

100 N, 250 N, 500 N, 1 kN, 2.5 kN, 5 kN, 10 kN, 20 kN, 30 kN, 50 kN |

100 N, 250 N, 500 N, 1 kN, 2.5 kN, 5 kN, 10 kN, 20 kN, 30 kN, |

|

|

lbf |

02, 1, 5, 10, 20, 50, 110, 220 |

0.2, 1, 2, 5, 10, 20, 50, 110, 220, 450, 1100 |

20, 50, 110, 220, 500, 1100, 2200 |

20, 50, 110, 220, 500, 1100, 2200 4400, 6600 |

20, 50, 110, 220, 500, 1100, 2200 4400, 6600, 11000 |

20, 50, 110, 220, 500, 1100, 2200 4400, 6600 |

|

Frame Type |

Guide Columns Floor-standing/ Tabletop |

1 Tabletop |

1 Tabletop |

2 Tabletop |

2 Tabletop |

2 Tabletop |

2 Floor-standing |

|

Test Zones |

Single/Dual |

Single |

Single |

Single |

Single |

Single |

Single or Dual |

|

Maximum Test Speed |

mm/min in/min |

3000 118 |

2000 78.7 |

2000 78.7 |

1020 40.16 |

750 30 |

1020 40.1 |

|

Minimum Test Speed |

mm/min in/min |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

0.005 0.0002 |

|

Position Resolution |

mm in |

0.00005 0.000002 |

0.00005 0.000002 |

0.00005 0.000002 |

0.00006 0.0000024 |

0.00006 0.0000024 |

0.00006 0.0000024 |

|

Power Requirements |

V AC

phase |

200 - 230 V AC, 5 Amps, 50 / 60 Hz, 1000 W |

200 - 230 V AC, 5 Amps, 50 / 60 Hz, 1000 W 1 |

200 - 230 V AC, 10 Amps, 50 / 60 Hz, 2000 W 1 |

200 - 230 V AC, 12 Amps, 50 / 60 Hz, 2400 W 1 |

200 - 230 V AC, 12 Amps, 50 / 60 Hz, 2400 W 1 |

200 - 230 V AC, 12 Amps, 50 / 60 Hz, 2400 W 1 |

|

Space Between |

mm |

100* |

100* |

425 |

420 |

420 |

400 |

|

Columns |

in |

3.94* |

3.94* |

16.73 |

16.54 |

16.54 |

15.75 |

|

Vertical Test Space |

|

|

|

|

|

|

|

|

Standard Length |

mm in |

1100 43.31 |

820 32.3 |

1200 47.2 |

1200 47.2 |

1200 47.2 |

1190 46.9 |

|

Extended Length |

mm in |

|

1120 44.1 |

1500 59.1 |

1500 59.1 |

1500 59.1 |

1490 58.7 |

|

Crosshead Travel |

|

|

|

|

|

|

|

|

Standard Length |

mm in |

900 35.4 |

650 25.6 |

1000 39.4 |

1000 39.4 |

1000 39.4 |

1000 39.4 |

|

Extended Length |

mm in |

|

950 37.4 |

1300 51.2 |

1300 51.2 |

1300 51.2 |

1300 51.2 |

|

Frame Height |

|

|

|

|

|

|

|

|

Standard Length |

mm in |

1520 59.84 |

1332 52.44 |

1616 63.6 |

1752 68.97 |

1752 68.97 |

1951 76.8 |

|

Extended Length |

mm in |

|

1632 64.25 |

1916 75.43 |

2052 80.78 |

2052 80.78 |

2251 88.6 |

|

Frame Width |

mm in |

560 22.05 |

704 27.7 |

794 31.3 |

826 32.5 |

826 32.5 |

861 33.9 |

|

Frame Depth |

mm in |

530 20.87 |

636 25 |

757 29.8 |

768 30.2 |

768 30.2 |

689 27.1 |

|

Frame Weight |

|

|

|

|

|

|

|

|

Standard Length |

kg lb |

60 132 |

112 246 |

175 385 |

305 671 |

305 671 |

395 869 |

|

Extended Length |

kg lb |

|

125 275 |

190 418 |

325 715 |

325 715 |

410 902 |

* For single-column load frames this measurement denotes the distance between grip center and column cover

|

|

|

Model 45 |

||||

|

|

|

C45.504 |

C45.504 Wide |

C45.105 |

C45.305 |

C45.605 |

|

Maximum Rated Force Capacity |

kN lbf |

50 11000 |

50 11000 |

100 22500 |

300 66000 |

600 132000 |

|

Force Capacity Options |

N, kN |

1 kN, 2.5 kN, |

1 kN, 2.5 kN, |

1 kN, 2.5 kN, |

150 kN, 200 kN, |

500 kN, 600 kN, |

|

|

|

5 kN, 10 kN, |

5 kN, 10 kN, |

5 kN, 10 kN, |

300kN |

|

|

|

|

20 kN, 30 kN, |

20 kN, 30 kN, |

20 kN, 30 kN, |

|

|

|

|

|

50 kN |

50 kN |

50 kN, 100 kN, |

|

|

|

|

lbf |

220, 500, 1100, |

220, 500, 1100, |

220, 500, 1100, |

33000, 44000, |

112400, 132000 |

|

|

|

2200, 4400, |

2200, 4400, |

2200, 4400, 6600, |

66000 |

|

|

|

|

6600, 11000 |

6600, 11000 |

11000, 22500 |

|

|

|

Frame Type |

Guide Columns Floor-standing/ Table-top |

2 Floor-standing |

2 Floor-standing |

2 Floor-standing |

2 Floor-standing |

2 Floor-standing |

|

Test Zones |

Single/Dual |

Single or Dual |

Single |

Single or Dual |

Single |

Single |

|

Maximum Test Speed |

mm/min |

750 |

750 |

750 |

750 |

254 |

|

|

in/min |

30 |

29.53 |

30 |

30 |

10 |

|

Minimum Test Speed |

mm/min |

0.005 |

0.005 |

0.005 |

0.005 |

0.005 |

|

|

in/min |

0.0002 |

0.0002 |

0.0002 |

0.0002 |

0.0002 |

|

Position Resolution |

mm |

0.000047 |

0.000047 |

0.000047 |

0.000049 |

0.000016 |

|

|

in |

0.0000019 |

0.0000019 |

0.0000019 |

0.0000019 |

0.0000000 |

|

Power Requirements |

V AC

phase |

200 - 230 V AC, 12 Amps, 50 / 60 Hz, 2400 W 1 |

200 - 230 V AC, 12 Amps, 50 / 60 Hz, 2400 W |

200 - 230 V AC, 22 Amps, 50 / 60 Hz, 4400 W 1 |

380 - 480 V AC, 20 Amps, 50 / 60 Hz, 5200 W 3 |

380 - 480 V AC, 20 Amps, 50 / 60 Hz, 5200 W 3 |

|

Space Between |

mm |

600 |

1000 |

600 |

650 |

750 |

|

Columns |

in |

23.62 |

39.37 |

23.62 |

25.59 |

29.52 |

|

Vertical Test Space |

|

|

|

|

|

|

|

Standard Length |

mm |

1220 |

1520 |

1220 |

1540 |

2000 |

|

|

in |

48.0 |

59.81 |

48.0 |

60.63 |

78.74 |

|

Extended Length |

mm |

1520 |

|

1520 |

1840 |

|

|

|

in |

59.8 |

|

59.8 |

72.44 |

|

|

Crosshead Travel |

|

|

|

|

|

|

|

Standard Length |

mm |

1000 |

1300 |

1000 |

1100 |

1750 |

|

|

in |

39.4 |

51.18 |

39.4 |

43.31 |

68.90 |

|

Extended Length |

mm |

1300 |

|

1300 |

1400 |

|

|

|

in |

|

|

51.2 |

55.12 |

|

|

Frame Height |

|

|

|

|

|

|

|

Standard Length |

mm |

2269 |

2554 |

2269 |

2535 |

3490 |

|

|

in |

89.3 |

100.6 |

89.3 |

99.8 |

137.4 |

|

Extended Length |

mm |

2569 |

|

2569 |

2835 |

|

|

|

in |

101.1 |

|

101.1 |

111.61 |

|

|

Frame Width |

mm |

1315 |

1710 |

1315 |

1362 |

1660 |

|

|

in |

51.77 |

67.32 |

51.77 |

53.6 |

65.35 |

|

Frame Depth |

mm |

957 |

957 |

957 |

1100 |

1272 |

|

|

in |

37.7 |

37.68 |

37.7 |

43.31 |

50.08 |

|

Frame Weight |

|

|

|

|

|

|

|

Standard Length |

kg |

1195 |

1700 |

1195 |

1605 |

3500 |

|

|

lb |

2629 |

3748 |

2629 |

3538 |

7700 |

|

Extended Length |

kg |

1265 |

|

1265 |

1695 |

|

|

|

lb |

2783 |

|

2783 |

3737 |

|

MTS CRITERION SERIES 40 SPECIFICATIONS - COMMON

|

Low Profile Force Accuracy* (Bending Beam and Shear Beam) |

± 0.5% of applied force |

± 1.0% of applied force |

|

Low Profile Force Range** (Bending Beam and Shear Beam) |

1 to 100% of rated force capacity |

0.5 to 1% of force rated capacity |

|

S-Beam Force Accuracy* |

± 1.0% of applied force |

|

|

S-Beam Force Range** |

1 to 100% of rated force capacity |

|

|

Rated Force Capacity at Max Test Speed |

100% |

|

|

Maximum Test Speed at Rated Force Capacity |

100% |

|

|

Speed Accuracy**** |

C41 & C42: ± 0.1% of set speed (≥2 mm/min) C43 & C44: ± 0.1% of set speed (≥1 mm/min)

C45: ± 0.1% of set speed (≥0.01 mm/min) C45: ± 0.2% of set speed (<0.01 mm/min) |

|

|

Displacement Accuracy**** |

± 0.008 mm or ± 0.05% of set displacement (whichever is greater) |

|

|

Strain Accuracy*** |

± 0.5% of applied strain |

|

|

Security Protection |

Over-force, travel limits, over-voltage and others |

|

|

Over-Force Protection |

110% |

|

|

Data Acquisition Rate |

Up to 5000 Hz |

|

|

Control Loop Rate |

5000 Hz |

|

|

Environmental Requirements Operating Temperature

Operating Humidity Storage Temperature Maximum Storage Humidity Maximum Altitude |

5 to 40°C 41 to 104°F 5 to 85% Non-condensing -18 to 49°C 0 to 120°F 90% Non-condensing 2000 Meters |

|

|

Motor & Drive System |

AC Servo Motor |

|

|

Ballscrews |

Pre-Loaded |

|

|

Position Measurement |

Encoder |

|

|

User Digital Inputs/Outputs (DIO) |

4 user Digital Inputs and 4 user Digital Outputs |

|

|

Encoder Capacity |

4 Encoders |

|

* Applicable onsite calibration services are available to meet ISO 7500-1, ASTM E4.

** Range dependent upon controller settings and operating environment.

*** Extensometer calibration services are available to meet ISO 9513, ASTM E83

**** This specification was derived from measurements using MTS specified methods under specified conditions and equipment. Subject to change without notice.

|

Electromechanical Attachment Specifications |

|

|

|

|

|

|||

|

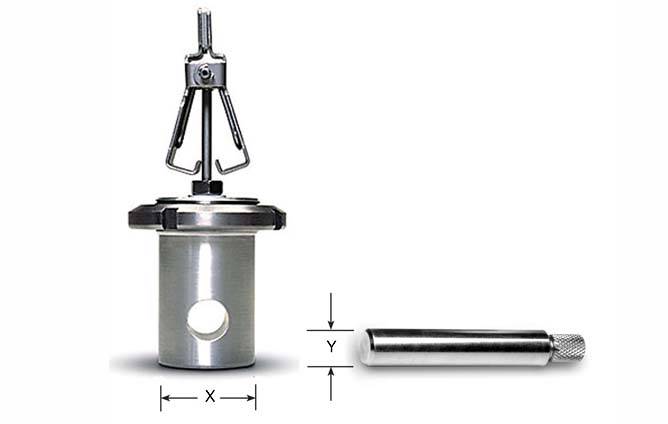

Clevis Pin Connection |

Type B |

Type C (AL) |

Type C (STL) |

Type D |

Type E |

Type F |

Type 20 |

Type 40 |

|

Max. Load Capacity |

10 N |

200 N |

2.5 kN |

150 kN |

300 kN |

600 kN |

30 kN |

100 kN |

|

Clevis Diameter (X) |

12.7 mm (0.50 in) |

15.9 mm (0.625 in) |

15.9 mm (0.625 in) |

31.7 mm (1.25 in) |

60 mm (2.36 in) |

90 mm (3.54 in) |

20 mm (0.787 in) |

40 mm (1.57 in) |

|

Pin Diameter (Y) |

4.7 mm (0.186 in) |

6.4 mm (0.25 in) |

6.4 mm (0.25 in) |

12.7 mm (0.50 in) |

28 mm (1.1 in) |

40 mm (1.57 in) |

10 mm (0.039 in) |

18 mm (0.71 in) |

Pre-packaged Advanced Test Templates for MTS TestSuite TW Software

|

Sample of the many Metals test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ASTM E8M |

Standard Test Methods for Tension Testing of Metallic Materials |

|

ISO 6892-1 |

Metallic Materials – Tensile testing at ambient temperature |

|

EN 10002-1 |

Tensile Testing of Metallic Materials |

|

ASTM E9 |

Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature |

|

ASTM E290 |

Standard Test Methods for Bend Testing of Material for Ductility |

|

ISO 7438 |

Metallic Materials – Bend Test |

|

ASTM E21 |

Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials |

|

ISO 783 |

Metallic Materials – Tensile testing at elevated temperature |

|

ASTM E517 |

Standard Test Method for Plastic Strain Ratio r for Sheet Metal |

|

ASTM E646 |

Standard Test Method for Tensile Strain-Hardening Exponents (n-Values) of Metallic Sheet Materials |

|

ASTM A48M |

Standard Specification for Gray Iron Castings |

|

ASTM A370 |

Standard Test Methods for Mechanical Testing of Steel Products |

|

Sample of the many Polymer test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ASTM D790 |

Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials |

|

ASTM D412 |

Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers – Tension |

|

ASTM D624 |

Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers |

|

ASTM D638 |

Standard Test Method for Tensile Properties of Plastics |

|

ASTM D695 |

Standard Test Method for Compressive Properties of Rigid Plastics |

|

ISO 178 |

Plastics – Determination of flexural properties |

|

ISO 1798 |

Flexible cellular polymeric materials – Determination of tensile strength and elongation at break |

|

ISO 527 |

Plastics – Determination of tensile properties |

|

ISO 604 |

Plastics – Determination of compressive properties |

|

ASTM D882 |

Standard Test Method for Tensile Properties of Thin Plastic Sheeting |

|

Sample of the many Construction Materials test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ASTM A370 |

Tensile Testing & Bend Testing Steel Rebar |

|

ISO 15630 |

Steel for the reinforcement and pre-stressing of concrete – Test methods – Part 1: Reinforcing bars, wire rod and wire |

|

ISO 1920-4 |

Testing of concrete – Part 4: Determination of flexural strength; Determination of tensile splitting strength |

|

ASTM A185/ A185M |

Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete |

|

ASTM A615M |

Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement |

|

ASTM A82/ A82M |

Standard Specification for Steel Wire, Plain, for Concrete Reinforcement |

|

EN 10080 |

Steel for the reinforcement of concrete. Weldable reinforcing steel |

|

ISO 15630-2 |

Steel for the reinforcement and pre-stressing of concrete – Test methods – Part 2: Welded fabric |

|

ASTM F606 |

Standard Test Methods for Determining the Mechanical Properties of Externally and Internally Threaded Fasteners |

|

Sample of the many Polymer Matrix Composite test standards that can be addressed using MTS TestSuite TW templates |

|

| Standard | Description |

|

ISO 527-4 |

Tensile Properties of Isotropic and Orthotropic Fibre-Reinforced Plastic Composites |

|

ISO 527-5 |

Tensile Properties of Unidirectional Fibre-Reinforced Plastic Composites |

|

ASTM D3039 |

Tensile Properties of Polymer Matrix Composite Materials |

|

ISO 14126 |

In-plane Compressive Properties of Fibre-Reinforced Plastic Composites |

|

ASTM D6641 |

Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture |

|

ISO 14125 |

Flexure Properties of Fibre-Reinforced Plastic Composites |

|

ISO 14129 |

In-Plane Shear Stress/Shear Strain Response of Fibre-Reinforced Plastic Composites |

|

ASTM D3518 |

In-Plane Shear Response of Polymer Matrix Composite Materials |

|

ISO 14130 |

Fibre-Reinforced Plastic Composite – Determination of Apparent Interlaminar Shear Strength by Short-Beam Method |

|

ASTM D2344 |

Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates |

We can provide pre-packaged templates for a wide array of additional materials, including: textiles, paper products, packaging, adhesives, foam, composites and more.

|

SHIPPING INFORMATION |

|

|

|

|

|

|

||||||

|

|

|

MODEL 41 |

MODEL 42 |

MODEL 43 |

MODEL 44 |

|

||||||

|

|

|

C41.103 |

C42.503 |

C43.104 |

C43.304 |

C43.504 |

C44.304 |

|

||||

|

Standard Length Frame

Dimensions - Crated

Weight - Crated |

mm in

kg lb |

820 x 1100 x 1760 32.28 x 43.31 x 69.29

110 242.5 |

1200 x 960 x 1570 47.2 x 37.8 x 61.8

247 543.3 |

1036 x 956 x 1865 40.8 x 37.6 x 73.4

312 686.4 |

2040 x 1140 x 1160 80.31 x 44.88 x 45.67

560 1232 |

2040 x 1140 x 1160 80.31 x 44.88 x 45.67

560 1232 |

2165 x 1100 x 930 85.24 x 43.31 x 36.6

600 1320 |

|

||||

|

Extended Length Frame

Dimensions - Crated

Weight - Crated |

mm in

kg lb |

|

1120 x 1070 x 1920 44.1 x 42.1 x 75.59

326 717.2 |

1150 x 1110 x 2200 45.27 x 43.7 x 86.6

438 963.6 |

2340 x 1140 x 1160 92.1 x 44.88 x 45.67

580 1276 |

2340 x 1140 x 1160 92.1 x 44.88 x 45.67

580 1276 |

2465 x 1100 x 930 97.05 x 43.31 x 36.6

695 1529 |

|

||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

MODEL 45 |

|

|

|

|

|

C45.504 |

C45.504 Wide |

C45.105 |

C45.305 |

C45.605 |

|

Standard Length Frame

Dimensions - Crated

Weight - Crated |

mm in

kg lb |

2620 x 1620 x 1600 116.5 x 78.74 x 55.5

1880 4136 |

2960 x 2000 x 1410 116.5 x 78.74 x 55.5

2150 4739 |

2620 x 1620 x 1600 103.15 x 63.78 x 62.99

1880 4236 |

114.96 x 65.35 x 65.35

2010 4422 |

3680 x 1960 x 1760 144.89 x 77.17 x 69.29

4050 8928 |

|

Extended Length Frame

Dimensions - Crated

Weight - Crated |

mm in

kg lb |

2920 x 1620 x 1600 114.96 x 63.78 x 62.99

1980 4356 |

- |

2920 x 1620 x 1600 114.96 x 63.78 x 62.99

1980 4356 |

3220 x 1660 x 1660 126.77 x 65.35 x 65.35

2210 4862 |

- |

Service and Support

Our experts are here to help keep you up and running.

Related Products, Parts or Accessories

Criterion® Custom Test Systems

Exceed® Electromechanical Test Systems

TestSuite Software

ReNew® Upgrades

Looking for more products?

Go to Solution FinderCONTACT US TODAY

Ready for a quote or need more information? We're here to help. Request A QuoteResources

Materials Test Equipment Accuracy

Traceable equipment calibration allows you to trust your tes…

Optimize TestSuite TW Templates

MTS systems integration engineer shows how to modify templat…

6 Tips for Accurate Compression Testing

MTS staff scientist outlines best practices for compression …

Tensile Testing 101

An MTS application engineer demonstrates a simple tensile te…

Bend Testing 101

An MTS application engineer demonstrates a 3-point bend test…

TestSuite TW Flexibility

Meet unique materials testing requirements with modifiabl…

Accurate Small Specimen Testing

Our smallest grips for your smallest specimens.

Versatile Monotonic Test Systems

MTS systems integration engineer describes monotonic test sy…

Faster Data Acquisition When Testing Composites

See how faster data acquisition provides the necessary level…

Increasing Production of PPE & Medical Consumables

See testing solutions that help accelerate production of cri…

Choose the Best Grip for Plastics & Rubber Testing

Quick review of various tensile testing grip types and their…

5x Faster Data Acquisition Rate

MTS Criterion Test Systems' controller has a 5000 Hz data ac…

New Optical Extensometer

Simplified non-contacting axial strain measurement & con…

DIC Helps Correlation of Physical Test Data & Model Simulations

Learn how this contract test lab is using DIC for better pre…

Tensile Testing of Structural Plastics

MTS application engineers discuss common solutions for tensi…