Safeguard high-value, one-of-a-kind aerospace test articles from dangerous unplanned unloading during complex and dynamic structural testing involving dozens - even hundreds - of hydraulic test actuators.

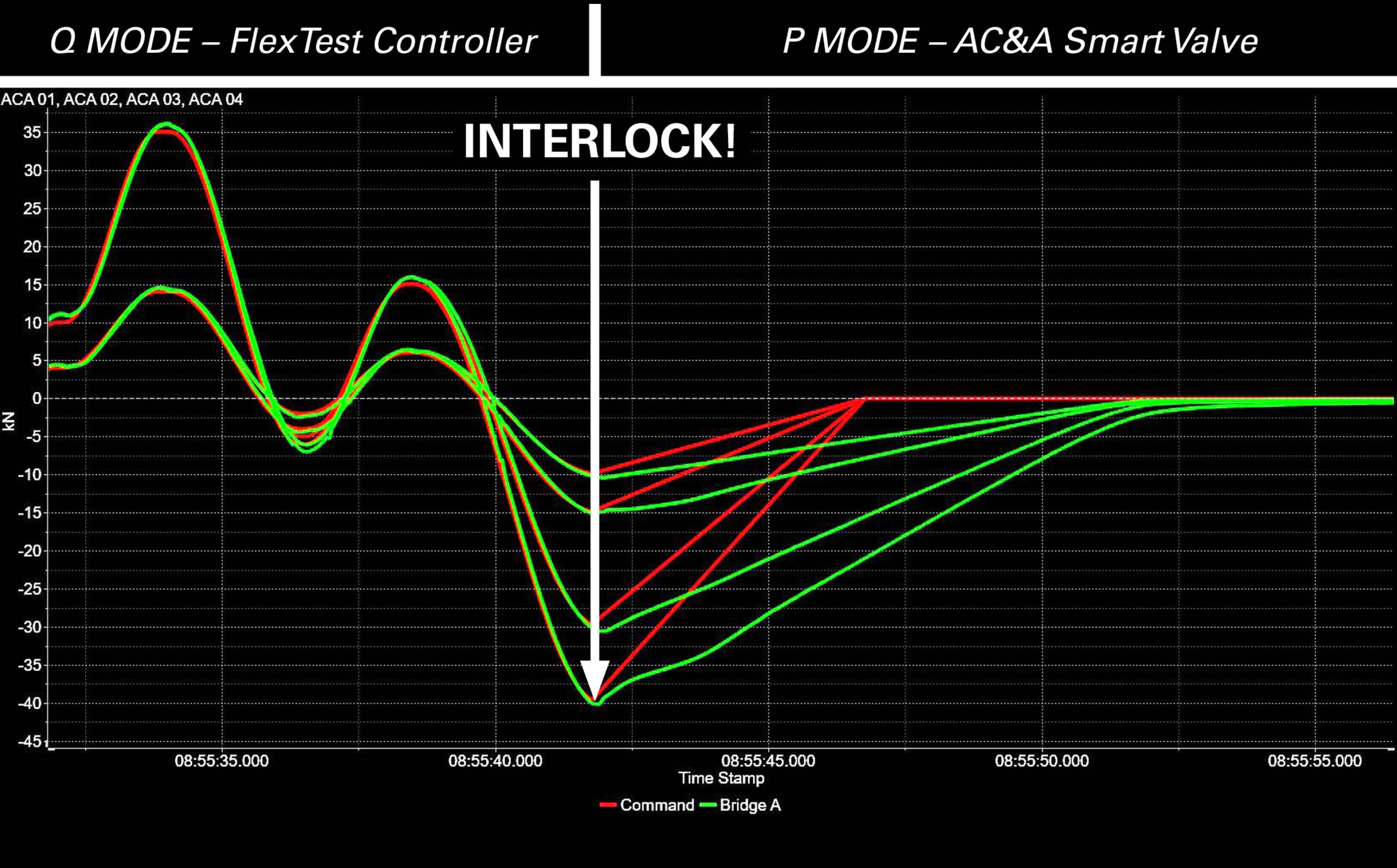

When an interlock condition is detected, the AC&A system isolates test actuators from hydraulic power and shifts the rig from flow control (Q Mode), governed by system controller, to pressure control (P Mode), which is driven by the distributed, actuator-mounted smart valves. The smart valves read pressure transducer data and calculate differential pressures for all actuators, then use these calculated loads to execute a uniform, synchronized ramp to zero load in 5-15 seconds.

Active Control & Abort (AC&A) System Components: