Q: Why do some test labs specify industrial actuators for aerospace testing?

Hennen: Many test labs want to save money. Others assume all actuators are equal. With either mindset, low purchase price motivates the buying decision. Actuators from manufacturers who serve other industries, such as mobile equipment, are available at a lower purchase price than those engineered for testing, and labs simply choose the less expensive option. It’s easy to assume that industrial and test actuators are equally suitable for static and dynamic testing. They look alike and appear to perform the same. But this is not the case.

Q: What differentiates test actuators from industrial actuators?

Hennen: Industrial actuators are less reliable and energy-efficient than test actuators, and they’re not nearly as precise. This is due to a series of innovations that clearly set test actuators apart from their industrial counterparts, including the fact that test actuators are fatigue-rated. Industrial actuators are actually the more expensive option in the long run. Their purchase price may be lower, but their cost of ownership often far exceeds that of test actuators.

Q: What is the connection between ‘fatigue-rated’ actuators and test article safety?

Hennen: ‘Fatigue-rated’ means test actuators are better able to protect valuable aerospace test articles. These very expensive, one-of-a-kind prototypes simply can’t be damaged in an unplanned way. Fatigue-rated actuators prevent this from happening.

The term ‘fatigue-rated’ refers to actuators that are designed to outlast the test. We remove the risk of failure during service through innovative engineering, high-performance parts and quality manufacturing. Fatigue-rated actuators can endure extreme numbers of cycles at intended loads throughout their expected life cycles. For example, MTS Series 201 actuators are designed to far exceed their rated load for millions of cycles, so structural failure will not occur when the actuator is operating at 100% of the rated load during a fatigue test.

Q: How is this different from non-fatigue-rated actuators?

Hennen: Non-fatigue-rated actuators are built for static loading and can operate at 100% of their rated load — at best. Typically, they are operating at the absolute threshold of load capacity under normal test conditions. Manufacturers of these actuators use lower-quality parts and apply fewer engineering hours to keep costs down, resulting in products that are much more prone to failure during service. They may perform sufficiently at first, but under the heavy cycling required for aerospace fatigue testing they will progressively degrade in performance and possibly incur structural failure well below their rated load capacity. These failures occur suddenly and can cause irreparable damage to multi-million-dollar test articles.

Q: Why do MTS Series 201 actuators deliver superior performance?

Hennen: The performance is a direct result of the close attention we pay to design. MTS Series 201 actuators include several subtle but critical engineering innovations that collectively enhance actuator reliability, energy-efficiency and precision.

Q: What are some of these engineering details?

Hennen: Our actuators feature bolted connections between rods and pistons, which are far superior to the threaded connections employed by many industrial actuator suppliers. Threaded connections cut costs, but are a frequent cause of structural failure. MTS actuators also integrate four fatigue-rated tie rods, one at each end cap corner, that are pre-loaded with torque exceeding the rated load of the actuator. This configuration creates the stiffness necessary to counter axial stresses and minimize the wearing effects of heavy cycling.

MTS actuators utilize high-performance polymer bearings with relatively large surface areas. They withstand high moments caused by cantilevering forces far better than brass bearings used in industrial actuators. Also, polymer bearings are far less likely to cause hydraulic system degradation. Brass bearings slough off abrasive particles as they wear, contaminating hydraulic fluid and accelerating pump and manifold degradation. Eventually, this affects system control.

MTS Series 201 actuators also include the same high-precision valves and transducers used with our top-of-the-line actuators. Such high-performance components will enable test labs to achieve the best possible control fidelity from their testing.

Q: How do MTS actuators improve energy efficiency?

Hennen: Friction is the primary cause of inefficiency in hydraulic distribution systems, so we use low-friction seals to provide ideal tolerance levels while introducing the smallest amount of friction. Seal frictional characteristics for MTS Series 201 actuators are 1% of the rated load, compared to the 10% that is typical for industrial actuators. What this means is that a 3000 psi industrial actuator requires 300 psi of energy just to move the piston, while a similarly rated MTS test actuator requires only 30 psi.

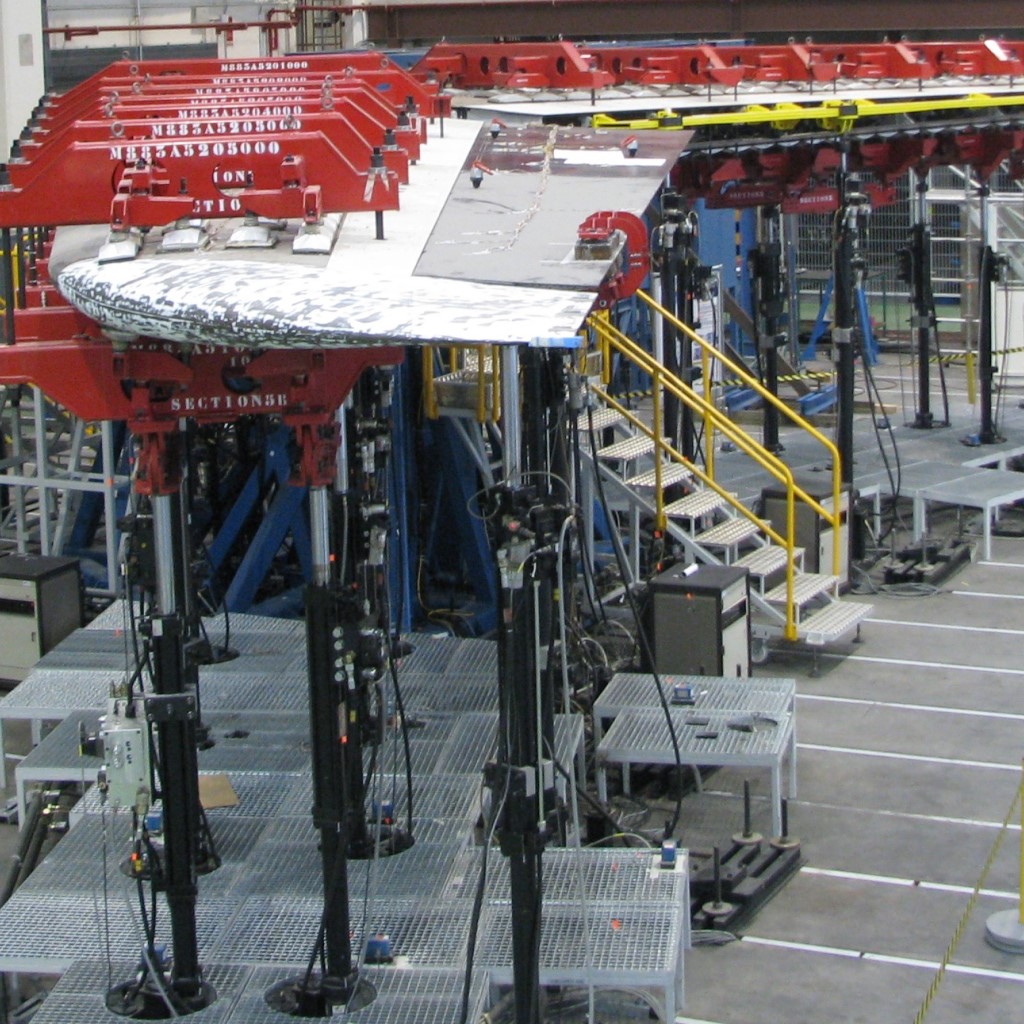

Multiplied by hundreds of actuators in a typical aerospace test setup, these inefficiencies really add up — especially during cyclic testing. Due to their high frictional characteristics, industrial actuators often require additional pumping power to move the fluid. If the hydraulic power unit is located across the test lab, a bigger, more expensive distribution system may also be required to maintain the necessary pressures, due to fluid frictional losses. In other words, labs are building larger hydraulic distribution systems to do the same amount of work.

Q: How will test labs benefit from using test actuators instead of industrial actuators?

Hennen: It will give them absolute confidence in the reliability of their static and dynamic test setup. By using actuators designed for testing, aerospace test labs will have a clear picture of how long the actuator will last and what loads it will withstand, across generations of tests.

Using test actuators will also help an aerospace test lab to optimize cost-efficiency. These actuators might have a slightly higher purchase price than industrial actuators, but this differential will easily be recovered through increased uptime and energy savings. In addition, by choosing MTS as their test solutions partner, test labs can tap into an unmatched reservoir of system integration expertise. We not only offer test-level expertise, but can also help aerospace test programs create the most efficient overall system design possible.

Hennen: Many test labs want to save money. Others assume all actuators are equal. With either mindset, low purchase price motivates the buying decision. Actuators from manufacturers who serve other industries, such as mobile equipment, are available at a lower purchase price than those engineered for testing, and labs simply choose the less expensive option. It’s easy to assume that industrial and test actuators are equally suitable for static and dynamic testing. They look alike and appear to perform the same. But this is not the case.

Q: What differentiates test actuators from industrial actuators?

Hennen: Industrial actuators are less reliable and energy-efficient than test actuators, and they’re not nearly as precise. This is due to a series of innovations that clearly set test actuators apart from their industrial counterparts, including the fact that test actuators are fatigue-rated. Industrial actuators are actually the more expensive option in the long run. Their purchase price may be lower, but their cost of ownership often far exceeds that of test actuators.

Q: What is the connection between ‘fatigue-rated’ actuators and test article safety?

Hennen: ‘Fatigue-rated’ means test actuators are better able to protect valuable aerospace test articles. These very expensive, one-of-a-kind prototypes simply can’t be damaged in an unplanned way. Fatigue-rated actuators prevent this from happening.

The term ‘fatigue-rated’ refers to actuators that are designed to outlast the test. We remove the risk of failure during service through innovative engineering, high-performance parts and quality manufacturing. Fatigue-rated actuators can endure extreme numbers of cycles at intended loads throughout their expected life cycles. For example, MTS Series 201 actuators are designed to far exceed their rated load for millions of cycles, so structural failure will not occur when the actuator is operating at 100% of the rated load during a fatigue test.

Q: How is this different from non-fatigue-rated actuators?

Hennen: Non-fatigue-rated actuators are built for static loading and can operate at 100% of their rated load — at best. Typically, they are operating at the absolute threshold of load capacity under normal test conditions. Manufacturers of these actuators use lower-quality parts and apply fewer engineering hours to keep costs down, resulting in products that are much more prone to failure during service. They may perform sufficiently at first, but under the heavy cycling required for aerospace fatigue testing they will progressively degrade in performance and possibly incur structural failure well below their rated load capacity. These failures occur suddenly and can cause irreparable damage to multi-million-dollar test articles.

Q: Why do MTS Series 201 actuators deliver superior performance?

Hennen: The performance is a direct result of the close attention we pay to design. MTS Series 201 actuators include several subtle but critical engineering innovations that collectively enhance actuator reliability, energy-efficiency and precision.

Q: What are some of these engineering details?

Hennen: Our actuators feature bolted connections between rods and pistons, which are far superior to the threaded connections employed by many industrial actuator suppliers. Threaded connections cut costs, but are a frequent cause of structural failure. MTS actuators also integrate four fatigue-rated tie rods, one at each end cap corner, that are pre-loaded with torque exceeding the rated load of the actuator. This configuration creates the stiffness necessary to counter axial stresses and minimize the wearing effects of heavy cycling.

MTS actuators utilize high-performance polymer bearings with relatively large surface areas. They withstand high moments caused by cantilevering forces far better than brass bearings used in industrial actuators. Also, polymer bearings are far less likely to cause hydraulic system degradation. Brass bearings slough off abrasive particles as they wear, contaminating hydraulic fluid and accelerating pump and manifold degradation. Eventually, this affects system control.

MTS Series 201 actuators also include the same high-precision valves and transducers used with our top-of-the-line actuators. Such high-performance components will enable test labs to achieve the best possible control fidelity from their testing.

Q: How do MTS actuators improve energy efficiency?

Hennen: Friction is the primary cause of inefficiency in hydraulic distribution systems, so we use low-friction seals to provide ideal tolerance levels while introducing the smallest amount of friction. Seal frictional characteristics for MTS Series 201 actuators are 1% of the rated load, compared to the 10% that is typical for industrial actuators. What this means is that a 3000 psi industrial actuator requires 300 psi of energy just to move the piston, while a similarly rated MTS test actuator requires only 30 psi.

Multiplied by hundreds of actuators in a typical aerospace test setup, these inefficiencies really add up — especially during cyclic testing. Due to their high frictional characteristics, industrial actuators often require additional pumping power to move the fluid. If the hydraulic power unit is located across the test lab, a bigger, more expensive distribution system may also be required to maintain the necessary pressures, due to fluid frictional losses. In other words, labs are building larger hydraulic distribution systems to do the same amount of work.

Q: How will test labs benefit from using test actuators instead of industrial actuators?

Hennen: It will give them absolute confidence in the reliability of their static and dynamic test setup. By using actuators designed for testing, aerospace test labs will have a clear picture of how long the actuator will last and what loads it will withstand, across generations of tests.

Using test actuators will also help an aerospace test lab to optimize cost-efficiency. These actuators might have a slightly higher purchase price than industrial actuators, but this differential will easily be recovered through increased uptime and energy savings. In addition, by choosing MTS as their test solutions partner, test labs can tap into an unmatched reservoir of system integration expertise. We not only offer test-level expertise, but can also help aerospace test programs create the most efficient overall system design possible.