CUSTOMER CHALLENGE

Knight Mechanical Testing (KMT) is a thriving independent mechanical testing laboratory headquartered in Fort Wayne, Indiana. Founded in 2007, the company earned its reputation by doing quality work for a cluster of orthopaedic implant manufacturers located in and around Fort Wayne. All three KMT founders worked as test engineers early in their careers, and this experience informed their understanding of what OEMs require from an independent test lab.

“The bulk of our work is on the final design of a product,” said KMT president Kevin Knight. “The manufacturer anticipates using the test data in a 510(k) submission or a similar document for an international regulatory body. Many international groups want to see raw test data along with the report.”

Pressure to accelerate time to market is intense in the medical device industry, so KMT’s customers expect results quickly. The sooner they gain approval, the sooner they enter the market and start selling. Of course, accuracy is equally critical. Control of mechanical loads is often dictated by the test protocol. For example, the ISO standard for hip stems requires tests to run within 2% of the target load at all times.

“When you’re running six hip stems up to 2,300 newtons, you need to make sure your load control is within the specification,” Knight said. “If there is an unexpected failure, you need to be able to demonstrate with your data that it was caused by the design of the implant, and not a mistake in test setup or execution.”

MTS SOLUTION

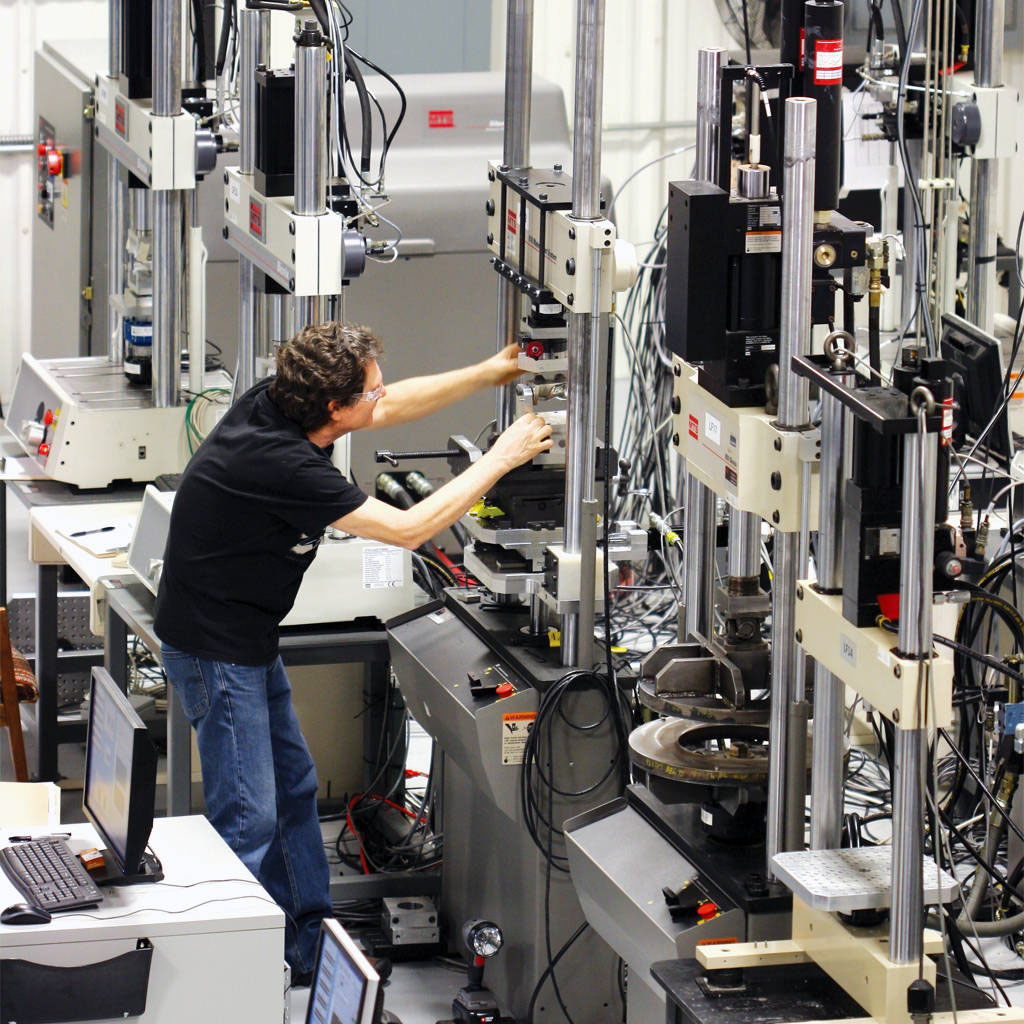

To meet the wide-ranging needs of its customers, KMT relies exclusively on test solutions from MTS. The lab uses a variety of MTS test equipment, from tabletop MTS Model 858 Bionix® Test Systems to floor-standing Model 810 load frames. All of these systems are integrated with MTS FlexTest® controllers and MTS MultiPurpose TestWare® (MPT) software.

“We’ve run fatigue loads as low as 10 newtons and as high as 50,000 or 60,000 newtons,” Knight said. “We run tests that other labs can’t perform. Earlier this year, we ran a fatigue test on ceramic femoral components for a customer at 41 kilonewtons and 30 Hz. The customer couldn’t find another lab that could do it. That’s a testament to the quality of our MTS systems.”

The versatilities of MTS test systems enable KMT to serve an increasingly diverse customer base. While the lab started out serving orthopaedic device manufacturers, its reputation has led to new opportunities in automotive components, aerospace and materials testing. The versatility available in a single MTS system is evident throughout the KMT lab.

“Right now we’re testing a clutch assembly for an automotive components manufacturer, and we’re running a dental implant on the next machine,” Knight said. “The clutch assembly is running at 10,000 pounds, and the dental implant is running at 15 pounds, both on the same kind of test frame. Each has a different load cell, but it’s the exact same frame, running off the same controller.”

Running side-by-side tests with vastly different parameters creates the potential for crosstalk, but Knight noted that MTS accumulators and robust system design prevent this from happening. He also relies on the ease of use of MPT software, which features a click-and-drag interface that simplifies the process of adding data acquisition routines. Knight recently used this capability to help a customer identify exactly what was happening with a polymeric specimen in the last few moments before it fractured.

CUSTOMER BENEFITS

The ability to respond quickly to customer requests is an important benefit of using MTS solutions. But for an independent lab like KMT, uptime is even more critical. The lab’s lineup of MTS test systems is typically running 24 hours a day, seven days a week, every day of the year. If the test frames aren’t running, then KMT is losing revenue. This is why MTS service is so important to KMT.

“Whenever there’s a challenge we can’t figure out, without exception, our MTS field service engineer either solves it for us or tells us what we need to do to solve it,” Knight said. “His knowledge of the products is second to none.”

Recently, KMT relied on MTS service to help them move to a larger facility. This meant relocating and recalibrating every piece of test equipment – including load cells with as many as 30 different capacities – as efficiently as possible.

“MTS worked with us to develop an aggressive schedule,” Knight said. “As soon as we had the equipment relocated and plumbed, the MTS team was ready to start calibrating. It was really amazing how quickly we were able to get the move accomplished. We moved everything on a Friday, and MTS was in on Monday to get us up and running. The whole process was basically invisible to most of our customers, and disruptions to the test schedule were minimal.”

Customers expect KMT to be available at a moment’s notice to meet any number of testing needs. This is how the lab has built its reputation, one that is growing to include new industries and new customers from coast to coast. In fact, nearly 90% of KMT’s business comes from repeat engagements and referrals.

“All of our customers end up being repeat customers because they have a good experience with our lab,” Knight said. “MTS equipment and support have definitely played a role in this dynamic.”