CUSTOMER CHALLENGE

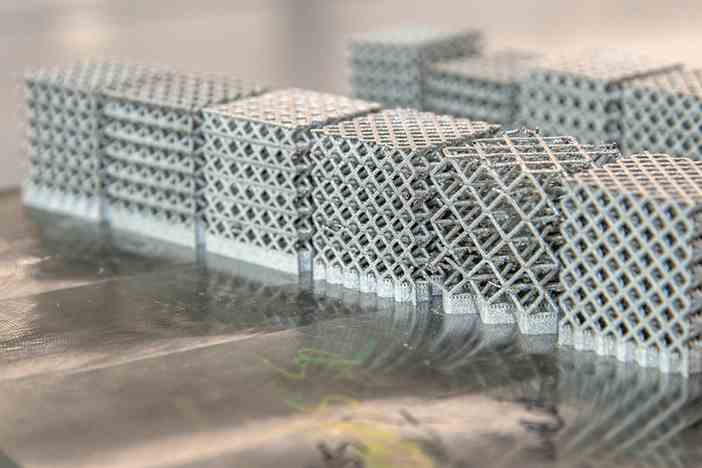

Products and components made with additive manufacturing processes often have complex shapes with variable wall thickness and thin sections that are difficult to test. Trying to create multiple standard-sized samples of the materials used in these products or components is time-consuming and expensive. It can also be problematic because of the potential for differing thermal history during manufacturing—a size effect in which thin walls in the range of tenths of a millimeter will exhibit different properties than those from a larger-sized sample. To assess the actual mechanical properties of the material, the samples must be representative, which means they must be extracted from a real component, or else made at the same location with the same orientation and in the same size range. For all these reasons, small specimen sample testing can provide a more accurate representation of material properties.

COMTES FHT, a private research institute in the Czech Republic, has been refining small specimen testing techniques for more than 15 years. Prof. Ing. Jan Džugan, R&D Director at COMTES FHT, established the mechanical testing laboratory in 2006, and small size testing methods were the first long-term research project at the institute. Currently, Džugan leads the effort to implement small size specimen testing requirements into standards for uniaxial testing under ASTM E28, and additive manufacturing under ASTM F42. His supervised Ph.D. thesis as well as many of his scientific papers are focused on small size specimens testing.

“Before we talk more about small size specimens, it would be good to clarify what that means to us,” says Džugan. “As standard size specimens for each test are different, we can roughly state, that small size specimen volume is about 100 times smaller. In the field of small size testing there are basically two groups of tests—direct testing with downsized specimens or indirect methods that measure some quantity linked to standard tests by specific correlation. We at COMTES FHT are more interested in the first group of test methods.”

COMTES FHT’s first research in the field of mini samples testing methods was focused on Small Punch Tests (SPTs) with which Džugan had previous experiences. “However, after some time we wondered why we should run SPTs, when we could perform tensile tests on the same material volume,” reports Džugan. “This turned to be successful move and we developed testing procedures relying on miniaturization of the standard specimens rather than on correlation between samples of different loading modes and strain rates. Over the years, our team consisting of the following research scientists: Dr. Pavel Konopík, Dr. Eva Chvostová, Dr. Radek Procházka, Martin Rund and Jindrich Vokac developed or adopted testing methods for determination of tensile properties, impact-based transition temperature determination, fracture toughness, fatigue crack growth rate tests, low- and high-cycle fatigue tests and creep tests. Most of these tests we can now also perform at non-ambient testing conditions.”

Though the small specimen testing techniques were originally developed to assess residual service life in the power industry, it became apparent that the small sample-based techniques were especially applicable to testing materials made with additive manufacturing.

TESTING REQUIREMENTS

Small specimen testing of additively manufactured materials presents specific challenges that drive a few requirements:

Load frame: Testing mini samples requires low speeds at standard strain rates, so stability at these very slow actuator velocities is crucial.

Strain measurement: Mechanical clip-on gages usually do not fit between the grips, so optical strain measurement is preferred. COMTES FHT uses both 2 and 3D DIC solutions. Džugan says, “For small flat objects and rather small strains, 2D DIC works well and you do not need so much computer power.”

Alignment: The current ASTM E1012 standard is not fully applicable to mini tensile sample alignment. COMTES FHT presently uses DIC systems to check and adjust specimen alignment during gripping and loading and expects that further process development will be needed to specify representative parameters for mini sample alignment.

Gripping: “There are currently no commercially available grips for mini sample tensile testing, so we had to develop them for ourselves,*” explains Džugan. “Proper gripping is a critical point because specimen plasticization can take place, so this has to be done with special care.” [*Note: Since this article was first published, MTS has developed grips for testing these types of mini samples. The MTS Advantage Mini Grips are designed for fast, accurate testing of extremely small specimens.]

MTS SOLUTION

COMTES FHT has been using MTS solutions in their lab since 2006. Their first MTS machine was a custom system designed for thermomechanical simulation of metal forming processes. Their second MTS system was a special high-rate Bionix® system with an axial/torsional main actuator plus a side actuator. Due to its versatility, accuracy and performance, this system was used for much of the development of mini samples testing methods. Džugan states, “On this system we tuned quasi-static as well as dynamic tensile tests (the system’s actuator velocity is over 1m/s). We also ran our first tensile tests with inductive heating units, and low- and high-cycle fatigue tests at room and elevated temperatures. We used this system to conduct fracture toughness tests on mini samples as well. After most of the development was done, we procured dedicated machines for these tests.”

CUSTOMER BENEFITS

The benefits of small specimen testing of additively manufactured materials are clear. The mini samples make it easier to do accurate local properties assessment. The small specimens save cost because they require a less material and minimal deposition time. The small specimen method is also ideal for cases where there is a shortage of the experimental material.

Today, COMTES FHT is a leader in the use of small specimen testing for additively manufactured materials; and is pleased to be working with MTS test systems to achieve their testing goals. Džugan says, “I have been working with MTS for more than 25 years in Europe and Asia and have had very positive experiences, which is the reason I’ve tried to establish a closer relationship with MTS in the field of development. We already have very good relationship with current local reps as well as with MTS people in Berlin and Minneapolis. I highly appreciate the support from MTS and the stability and reliability of their test equipment, and I look forward to working with them in the future.”