Backed by a PhD in mechanical metallurgy and several decades of experience in high-temperature testing, MTS R&D Engineer and Staff Scientist Erik Schwarzkopf discusses the challenges of maintaining precise control of testing temperatures.

Q: Why is temperature so important to materials testing, especially isothermal LCF or HCF tests?

A: Engineers need to understand how material properties change at different temperatures so they can design products and components that perform reliably at the temperatures that occur in actual operating environments. Low-cycle fatigue (LCF) and high-cycle fatigue (HCF) tests last many hours, so temperature stability is critical. Over the course of the test, a drift of five or ten degrees can add significant uncertainty to the results.

Q: How do you measure temperature in a typical test configuration?

A: The most common method is a thermocouple, which has two metal conductors (wires). Current flow across the junction of the wires is proportional to the temperature at the junction. The wires are typically attached to the specimen so that the temperature at the junction is that same as the temperature of the specimen. For high-temperature testing, researchers use Type R thermocouples with platinum-rhodium wires, although Type K thermocouples with chromel-alumel wires are a less expensive choice. Lower-temperature, high-sensitivity applications require Type J iron-constantan thermocouples.

Q: How do you control temperature during a test?

A: The output from a proportional-integral-derivative (PID) controller can be used to energize a heating system surrounding the specimen. Within the chamber or furnace, you can use one or more controllers to manage different zones of the interior space. The idea is to control the temperature so that the temperature across the specimen remains uniform, even if there are pockets of variable temperature elsewhere.

Q: Is the temperature really that different throughout the furnace?

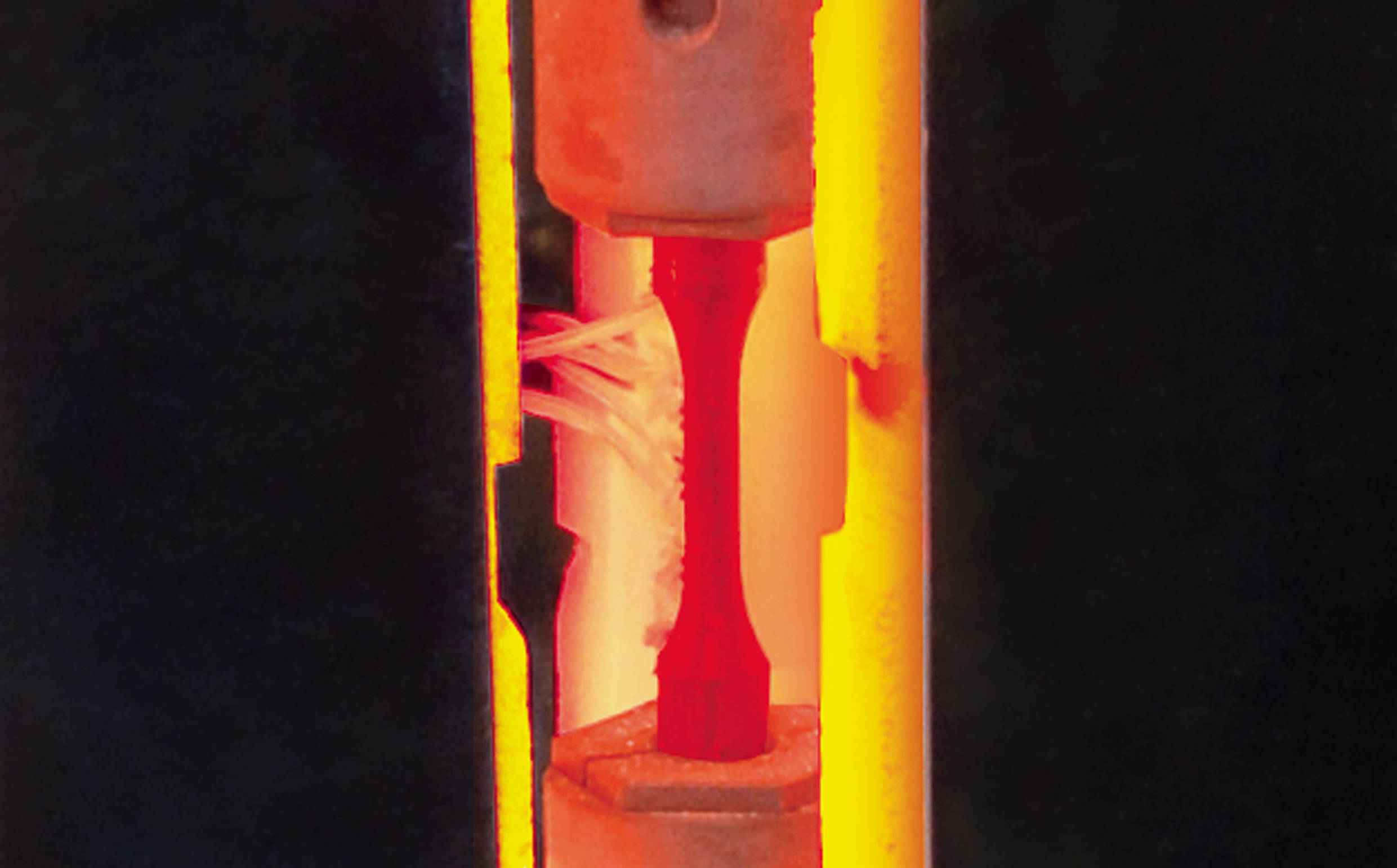

A: Yes. If the temperature controller sends the same instructions to three heating elements in the furnace, the gradient across the specimen will be large enough to call test results into question. That is unacceptable, of course. It is also unnecessary. It is possible to control temperature effectively, but you have to understand the thermodynamic mechanisms at work. Gradients occur because the load train extends outside the furnace to the load cell and actuator, which are at ambient temperature. Heat in the furnace is transferred to those ambient portions via conduction while the heating elements continue to add heat, but these actions do not happen at the same rate. With multiple zone control, we create “buffers” that push the larger gradients away from the specimen gage length, out toward the shanks or even the pushrods. This way, the gradient in the reduced section of the specimen will be acceptably small.

Q: How small should the gradient in the specimen be?

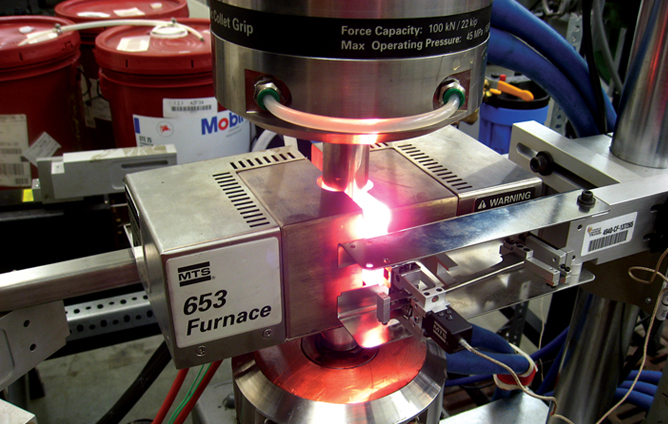

A: It depends on the standard. The various national and international LCF and HCF test specifications do not agree about gradients. Generally, the maximum gradient in the gage length is a few percent of nominal test temperature. So, if the nominal test temperature is 500°C, the reduced section should have a gradient of no more than 5°C to 10°C, or one to two percent. In a well-designed test system, the gradient in the reduced section can be held to within 1% of the desired temperature. The MTS Model 653.04 three-zone furnace, for example, can hold the gradient to ±2°C over a 25 mm gage length at 800°C nominal test temperature, which is well within ASTM and ISO specifications.

Q: How long does it take to reach the desired test temperature?

A: It can take an hour to ramp up, soak the specimen, and achieve equilibrium in the specimen and load train. If you ramp up too quickly, you can overshoot and damage the specimen or add even more time for cooling and reheating. Many labs have tried to minimize ramp up time over the years, because it can hinder productivity. For some tensile tests, you can preheat specimens and load trains in spare furnaces, then install them in the test system when the time comes. Other labs have experimented with variable heating rates in each furnace zone, which can help reduce soak times. The high-temperature LCF and HCF templates for MTS TestSuite™ MP Elite software, for example, use complex profiles to bring the outer zones up to temperature quickly, then carefully ramp the inner zone that contains the specimen. In many cases, however, the test specification dictates soak time.

Q: Is the bigger, better furnace always the right choice?

A: It depends on what you mean by “bigger” and “better.” A furnace may have a higher maximum temperature, more furnace insulation, a larger interior, longer heated zones, or more zones of control. The question to ask is, what are the tradeoffs? More zones of control give you smaller gradients in the specimen, but they cost more. Longer heated zones reduce gradients too, but they require high-temperature pushrods. More insulation improves stability but makes it harder to recover from overshoot. Using a 1000°C furnace for a 150°C test will compromise temperature control. The list goes on.

Q: What else is important to consider for precise temperature control?

A: Before you select accessories, such as a furnace or grips, you have to think about the application as a whole: desired test temperature, specimen geometry, gradient and test time. You also have to think about the way you will heat up a specimen and manage temperature during the test. The most common method in an isothermal test is using a resistance furnace with thermocouples in contact with the specimen. The thermocouples are spot-welded to the specimen shanks, not the reduced section, because they can become crack initiation sites. Most important, researchers should take full advantage of the body of knowledge that exists now for high-temperature testing. Not so long ago, the normal approach was trial and error. Today, you can choose a smarter path and get more accurate results.