Keeping dust and debris from damaging your test equipment when testing polymer matrix composites, fiber reinforced plastics and ceramic matrix composites can be challenging. Follow these simple suggestions to help protect valuable testing equipment and achieve better results.

Use Physical Barriers

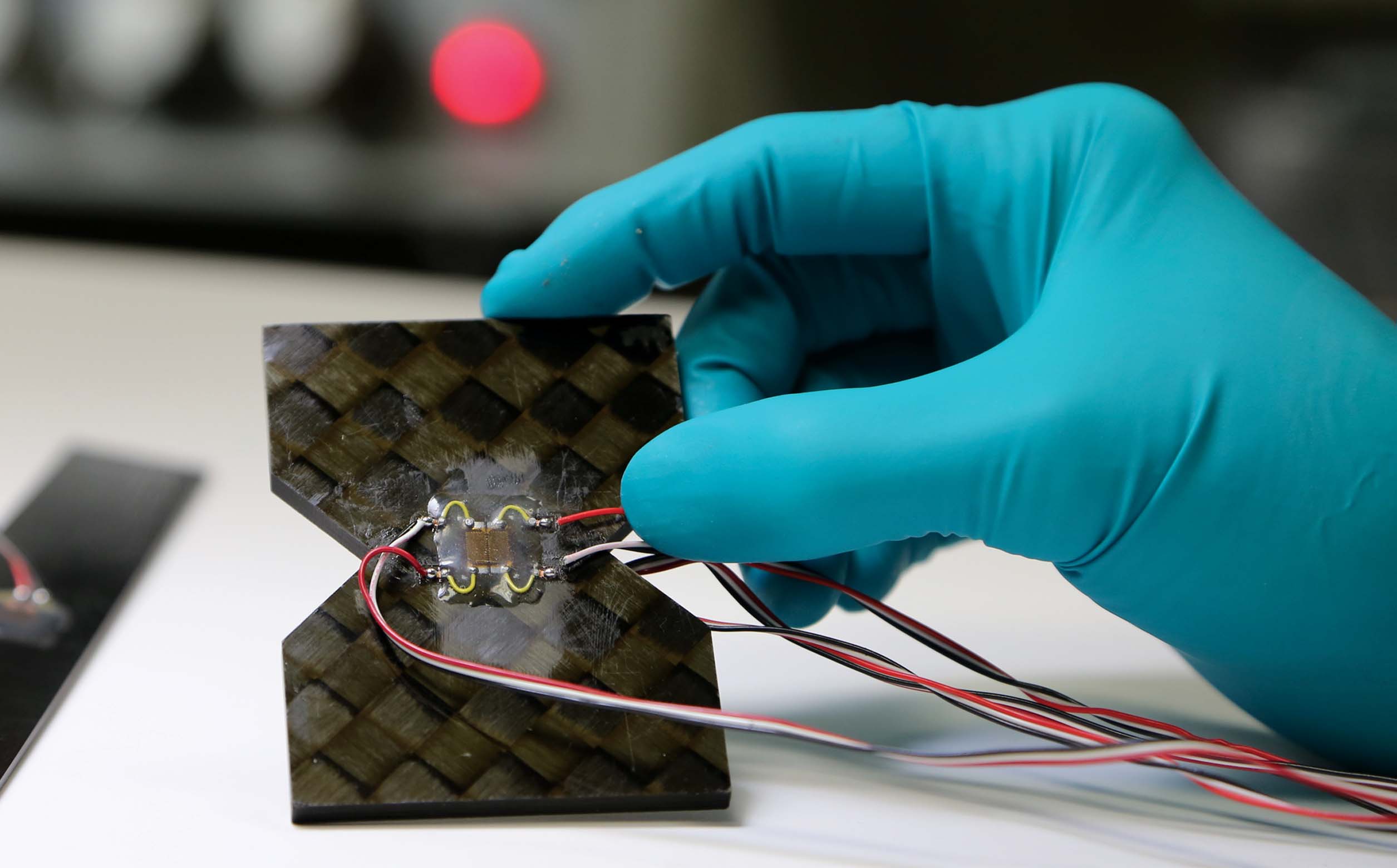

- Wear latex gloves to protect your hands and the specimen.

- Shield yourself and the equipment from debris and dust with a Test Area Enclosure or an environmental chamber.

- Protect the grips by using a piece of latex rubber sheeting with the appropriate temperature rating to make a barrier between the base of the specimen and the top of the lower grip. The sheeting needs to have a hole that is slightly smaller than the specimen, so that it can be stretched over the specimen and then laid flat across the top of the lower grip.

- In an excessively dusty environment, place the standalone controller in an industrial cabinet that includes additional dust protection to prevent contamination.

Start with a Clean Specimen

- Make sure the specimen is dust-free before the test.

- Remove loose fibers so they do not fall into the grips during loading.

Vacuum Early & Often

- Remove fibers and specimen dust after each test with an industrial-rated vacuum cleaner designed for use with these materials.

- If possible, the vacuum cleaner should automatically start just before the specimen breaks so that most of the dust and debris can be collected before it compromises the test equipment.

- In servohydraulic systems, fibers or dust can enter the low-pressure seal area and cause leaking and damage as well as contaminate the system’s hydraulic fluid supply. Since composite testing debris like carbon fibers, glass fibers and ceramic dust function as abrasives, even smaller particles can be particularly damaging to hydraulic components. The best way to protect against this damage is to regularly use an industrial vacuum cleaner to remove the debris and dust.

Minimize Lubrication

- For grips, only use a minimal amount of grease to ensure that the wedges move easily in the grip body during closing and opening of the grips. Excessive use of grease will collect more fibers and specimen dust, instead of protecting the grips.

- For electromechanical systems, only lubricate the lead screw and ball screws slightly once a year. Inspect from time to time, and if contamination is noticed, clean the system.

Address Leaking Components Immediately

- If a significant leak exists in any of the system components, there is a high chance that fibers, dust or particles will get into the hydraulic fluid supply system, which can cause major problems in all test systems and hydraulic components that are a part of the hydraulic distribution system.

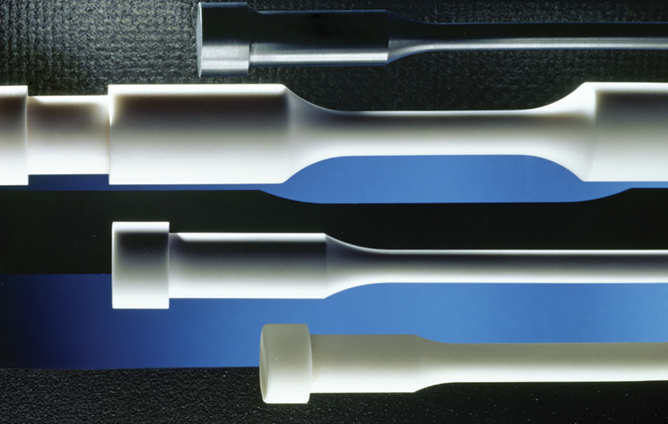

- Do not start a fatigue test with a leaking grip! At the first sign that some of the fibers are working into the grip bore or as soon as a noticeable oil leak occurs, the grips should be torn down, cleaned and re-sealed. Ensure that the working area is clean, to prevent contamination during the grip rebuilding. This cleaning is an inconvenience that may delay testing, but it is a preferable alternative to costly repairs.

- If the system actuator starts leaking, replace the actuator seals or at least check them for contamination. Using an environmental chamber and keeping the system clean will also help protect the actuator seals and minimize premature actuator wear and damage.

Keep Grips & Accessories Clean

- Clean the grips and fixtures with a vacuum cleaner after each test.

- At the end of the day, remove the wedges if applicable and carefully clean all components and surfaces of the grips.

- For fixtures that have bearings that are not able to move freely, clean and lubricate the bearings according to their type. Stainless steel bearings should be soaked in a strong solvent and vigorously rotated in the solvent until the grease and debris is removed. The bearing must be completely dry after the cleaning before it is lubricated again with white lithium grease. If the bearing still does not move freely after cleaning, it should be replaced.

- For environmental chambers, use a vacuum system to clean the dust from the inside of the chamber, and finish by cleaning the surfaces with a soft cloth.

- Keep extensometers clean and inspect them regularly for contamination. When not in use, remove them from the test area.

Protect Hydraulic System & Components

- If hydraulic hoses need to be disconnected, the environment must be completely dust free to prevent contamination of the hydraulic fluid. Contaminated fluid will damage the entire hydraulic system.

- Before removing a servovalve, everything should be cleaned very carefully. Use an appropriate solvent to wipe everything off before disconnecting the valve.

- Change oil filters as recommended in the maintenance manual for the hydraulic systems.

- If the hydraulic power unit is located in the test lab, and physical barriers are not present, then a hydraulic isolator could be used to minimize the risk of dust entering the oil reservoir through the breather and contaminating the hydraulic fluid.

- Check hydraulic fluid cleanliness at least once a year, or when the grips or actuator seals have been exchanged.

Additional Considerations for Servohydraulic Load Frames

- Using an actuator bellow will help protect the system. Connect the bellow below the grip and then it can rest on the base of the frame or be kept in place by magnetic forces.

- A crosshead-mounted actuator can minimize the risk of contamination, but there are other issues that come in play. For example, the alignment fixture and the load cell need to be mounted to the base. The load cell could be mounted to the moving actuator, but this might require acceleration compensation measures.

- Both a base-mounted and crosshead-mounted actuator will drop down when the system’s oil supply is shut off, but the crosshead-mounted actuator could damage the surfaces of the broken specimen, if the broken parts are not removed after the test. A base-mounted actuator is easier to service and as with a crosshead-mounted actuator, it is critical to keep the system and actuator clean.

- When testing without a physical barrier, use a standalone hydraulic grip supply which can be placed away from the testing area to help prevent fibers and dust from getting into hydraulic supply system.

- The columns need to be cleaned, before the crosshead is moved, to prevent fibers and dust from causing damage when trapped in the hydraulic crosshead clamping system.