Pantograph Wear & Performance System

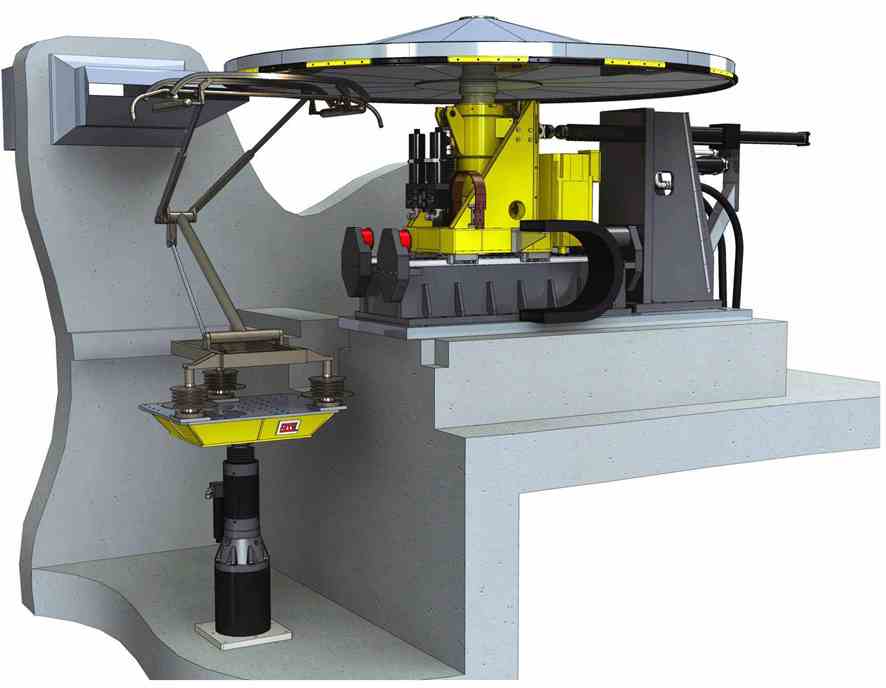

Apply precise longitudinal, horizontal and vertical loading to railway pantograph specimens to replicate the highly complex and dynamic pantograph-catenary (trolley wire) operating environment. This high fidelity simulator features multiple test modes, enabling manufacturers to study the complete operational dynamics of pantograph designs under a wide array of real-world scenarios.

Applications

Test Specimens

Key Product Features

Versatile

Play out actual time histories and perform parametric studies to replicate a wide variety of real-world operating conditions

Cost Efficient

Laboratory test requires only pantograph assembly and trolley wire specimen - no rail car or track needed

Accurate / Repeatable

Enables detailed measurement of small performance differences in test article response

Accelerated Testing

Enables studies of pantograph suspension dynamic response using advanced mHIL techniques

Technical Overview

|

|

Disc Vertical |

Zig Zag |

Speed |

Table Vertical |

|

Displacement |

± 100 mm |

± 350 mm |

- |

± 75 mm |

|

Velocity |

900 mm/s |

250 mm/s |

550 kgh |

400 mm/s |

|

Acceleration |

6 g |

2 g |

< 60 seconds |

6 g |

|

Frequency |

10 Hz |

15 Hz |

- |

30 Hz |

Service and Support

Our experts are here to help keep you up and running.